Analysis of Plastic Injection Mold Products for Window Handle

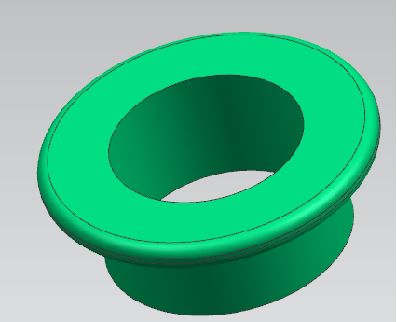

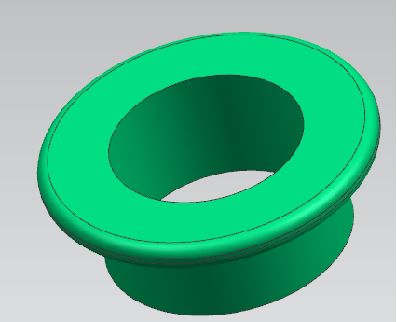

spacer plastic injection part

一.Plastic products

1.Process analysis of plastic parts

First,this product belong to outer product,the product weight is

0.31g,the material is Acteal,surface polishing need to make high

polishng,the customer's request need make 16 cavaties mold.We check

the all request and give the DFM report to customers.

2.Calculate the volume and mass of plastic parts

The calculation of the quality of plastic parts is to select the

injection machine and determine the number of cavities.After

calculation

The volume of the plastic part is V=1.008. According to Appendix B,

the Acteal density is P=1.009g · mm-3, therefore the mass of the

plastic part is 0.31g,The mold structure of the first mock

examination and two pieces, considering its overall dimensions, the

pressure required during injection Force, preliminary selection of

HTF90-I injection machine.

3.Determination of process paraeters fmor plastic injection molding

According to Appendix H, the forming process parameters of Nylon

can be selected as follows

Barrel temperature: front section 200-210 ℃, middle section 210-300

℃, rear end 180-200 ℃

Nozzle temperature: 190-200 ℃

Mold temperature: 50-80 ℃

Injection pressure: 70-120MP

Maintaining pressure: 50~70MP

Injection time: 3-5 seconds, holding time 15-30 seconds, cooling

time 15-30 seconds

Forming cycle: 40-70s

4.Selection of injection mold parting surface

In mold design, the selection of the parting surface is crucial as

it determines the structure of the mold.The selection of the

parting surface should be based on the principles of the parting

surface and the forming requirements of the plastic part,The

parting method shown in the figure can reduce the complexity of the

mold and reduce the number of molds,The processing difficulty of

the tool is also convenient for demolding the mold.

5. Principles for selecting parting surfaces:

a. The maximum contour of the plastic part, otherwise the product

cannot be taken out

b. Beneficial for smooth demolding of plastic parts and preventing

suction of front molds

c. Beneficial for ensuring the accuracy requirements of plastic

parts

d. Meet the appearance quality requirements of the product

e. Facilitate the processing and manufacturing of molds